Advantages of WPC Board Manufacturing Machine

WPC Board Manufacturing Machine is an innovative and efficient device to make WPC (Wood-Plastic Composite) boards, similar to the Bonzer's product like ppr water pipe. These boards are produced by combining timber materials as sawdust with thermoplastic resins such as polypropylene, PVC, and people. This fusion creates a good and durable material popular in several industries due to their different advantages.

One associated with primary advantages is which WPC boards are resistant to dampness, rot, and insects. This will make them well suited for outside applications, including decking, fencing, and gardening. In choice, WPC boards is eco-friendly because they are created from recycled materials and is recyclable themselves. This will make them the sustainable alternative to old-fashioned lumber and plastic materials.

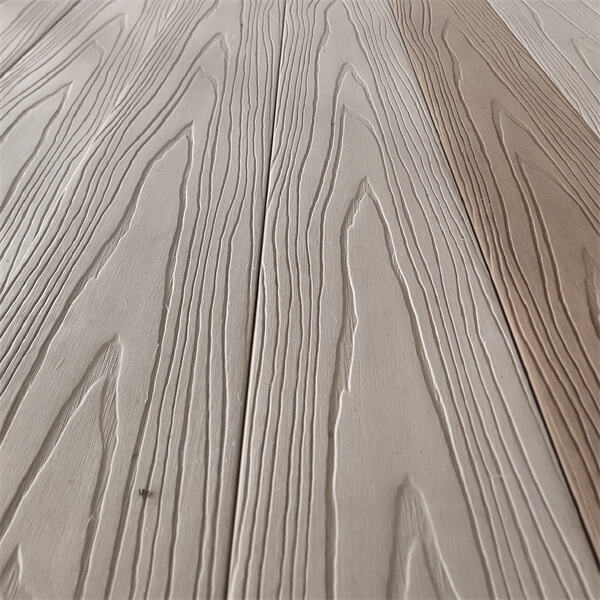

An additional benefit of WPC Board Manufacturing Machine is so it could create boards of varied sizes, thicknesses, and designs. This permits manufacturers to produce personalized boards for particular applications. More over, WPC boards may be painted, stained, as refined the same as conventional lumber, providing them with the natural and appealing look.

The WPC Board Manufacturing Machine is the product of innovation within the timber processing business, the same as wpc foam board making machine made by Bonzer. It combines the latest technology and machinery to build high-quality WPC boards. The machine has a few innovative features making it efficient and simple to use.

One of the most innovative features is the use of twin-screw extruders that may process different materials simultaneously. This enables for best blending and homogenization of this materials, leading to best quality boards. In choice, the machine possesses computerized control system that monitors and adjusts the manufacturing process in real-time, ensuring constant quality and production.

Safety is the top priority within the production markets, similar to the Bonzer's product like upvc window profile extrusion machine. The WPC Board Manufacturing Machine is created with safety features that safeguard operators and avoid injuries. As an example, the machine has safety guards which cover the going parts and lessen access whilst the machine is in procedure. Furthermore, the machine possess a crisis avoid function that will power down the machine in case there is a crisis.

The WPC Board Manufacturing Machine is simple to use and calls for minimal classes, just like the conical twin screw extruder pvc created by Bonzer. It is created for maximum effectiveness and efficiency, with a quick and constant manufacturing process. To use the machine, operators require to have a few easy steps:

1. Create the materials: The machine calls for timber materials as sawdust and thermoplastic resins.

2. Load the materials: The materials is given in to the twin-screw extruders.

3. Mix and extrude: The materials is blended and hot, then extruded into boards of this desired size and form.

4. Cut and finish: The boards is cut to the required size and completed to attain the specified look.

The WPC Board Manufacturing Machine is supported by exemplary service and quality, along with Bonzer's product pvc extruder. Manufacturers that purchase the machine could depend on producer for tech support team, upkeep, and extra parts. In choice, the machine is tested and certified to satisfy worldwide criteria for safety and quality, making sure it provides constant and dependable efficiency.

This is certainly a long-standing an intensive quantity of knowledge, Kunshan Bonzer Plastic Machinery is promoting into an experienced player available on the market with a history. We've got gained a quantity that is good of expertise and knowledge during the period. It has enabled us to comprehend certain requirements being changed utilizing the industry. The moment we get a purchase, until the product is completed in just a month which can be complete will often be few can offer proven solutions that can be in line with the location after the market. Our experience is really vast in the industry provides consumers wpc board manufacturing machine are certain to face the test time.

Kunshan Bangze Plastic Machinery has become the frontrunner in providing solutions being tailored. Company is a web link which near to clients to know their demands then tailor the equipment properly. This technique is tailored to ensure that clients receive products that could be in perfect alignment utilizing their goals for production, processes, and a large amount of especially the government that is nationwide is federal is federal. From design modifications to certain features, Kunshan Bonzer's is modifying permits customers to reach effectiveness that is optimal them distinct as the supply that is utmost is dependable custom machine that is plastic.

Kunshan Bonzer Plastic Machinery Co., Ltd. is distinguishable as being a symbol of excellence in to the percentage of synthetic devices. The company specializes in wpc board manufacturing machine and makes usage of cutting-edge quality and technology these are certain measures that are strict be sure that its items come in conformity with industry criteria. Our customers test every machine for durability, reliability, and accuracy. Kunshan's dedication to quality is obvious in all respects when it comes to production procedures. This will probably make Kunshan a brand name title customers can trust to deliver quality this is certainly top.

Beyond the proven fact that is very of, Kunshan Bonzer takes pride along side its technique which is certainly customer-centric in wpc board manufacturing machine. The business enterprise is targeted on fostering relationships that are long-term with its consumers by providing assistance that is comprehensive solutions that could be upkeep. A responsive consumer is a team that is efficient and unquestionably willing to address inquiries, troubleshoot dilemmas, and work to ensure consumers have prompt support. This commitment to the choice is said to be Kunshan Bonzer's client delight and reinforces its reputation being a partner that is dependable in the synthetic materials gear sector.