Features:

Polyvinyl chloride (PVC) siding panels offer a durable, low-maintenance solution for exterior cladding. Resistant to weather, rot, and insects, PVC siding ensures longevity without the need for frequent upkeep. Its versatility presents a range of styles, colors, and textures, mimicking the aesthetics of wood or shingles. Lightweight construction facilitates easy installation, and some variants boast insulation properties for enhanced energy efficiency. While the initial cost may be higher, long-term savings arise from minimal maintenance. PVC siding is eco-friendly, being recyclable and available with recycled content, making it a cost-effective, environmentally conscious choice for homeowners.

1.Conical twin extruder

This specialized machine features two interlocking screws within a conical barrel, effectively processing PVC compounds for siding production. The conical design enhances material mixing and melting, ensuring a homogenous blend. With precise control over the extrusion process, it contributes to the creation of durable and high-quality PVC siding panels. The conical twin-screw extruder is integral to achieving consistent performance and aesthetics in the manufacturing of siding materials.

2.Single screw co-extruder

ASA co-extrusion significantly enhances siding panels, providing superior durability and aesthetic benefits. Acrylonitrile Styrene Acrylate (ASA) outer layers shield against UV rays, preventing color fading and ensuring long-lasting vibrancy. This co-extrusion process enhances resistance to weather, impact, and scratches, contributing to extended panel lifespan. ASA's advanced weathering properties make siding panels resilient to harsh elements, maintaining their appearance over time. Additionally, the co-extrusion technology allows for a diverse range of colors and finishes, enabling homeowners to achieve customized looks that withstand environmental stressors. ASA co-extruded siding panels thus offer an optimal combination of performance, aesthetics, and longevity for exterior applications.

3.Dies

Dies play a crucial role in a siding panel extrusion line, shaping and forming the molten material into the desired profile. These specialized tools define the panel's dimensions, surface texture, and overall appearance. Precise die design is essential for producing high-quality siding panels with consistent and accurate specifications.

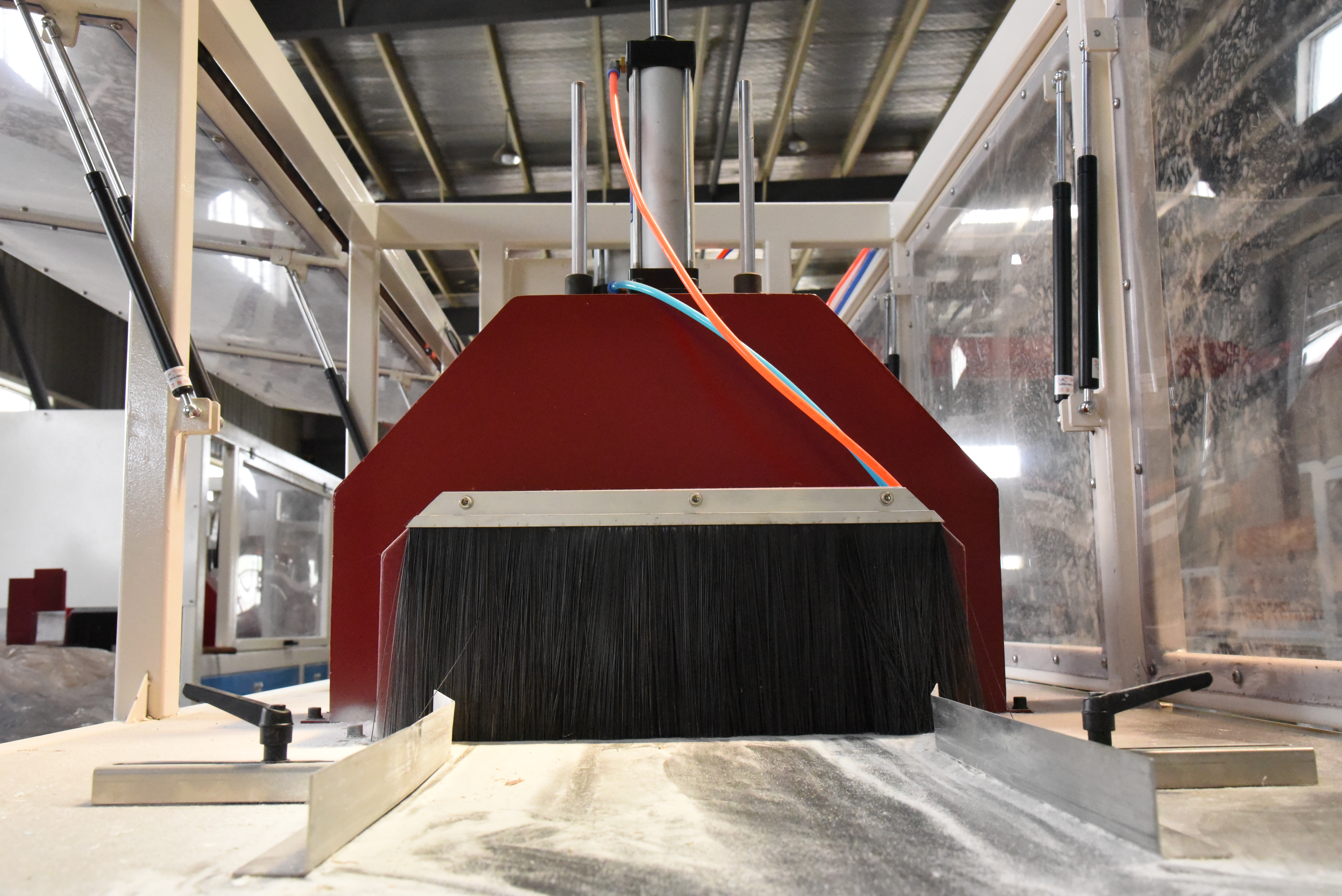

4.Lamination & embossing machine

Integrating a lamination and embossing machine into a siding panel extrusion line enhances product aesthetics and durability. Lamination adds a protective layer, shielding panels from environmental elements, while embossing imparts textured designs, offering a visually appealing finish. This streamlined process not only ensures high-quality surface treatments but also improves resistance to wear and tear. The combination of lamination and embossing in the extrusion line elevates the overall appeal of siding panels, meeting both functional and aesthetic demands for a more resilient and visually striking end product.

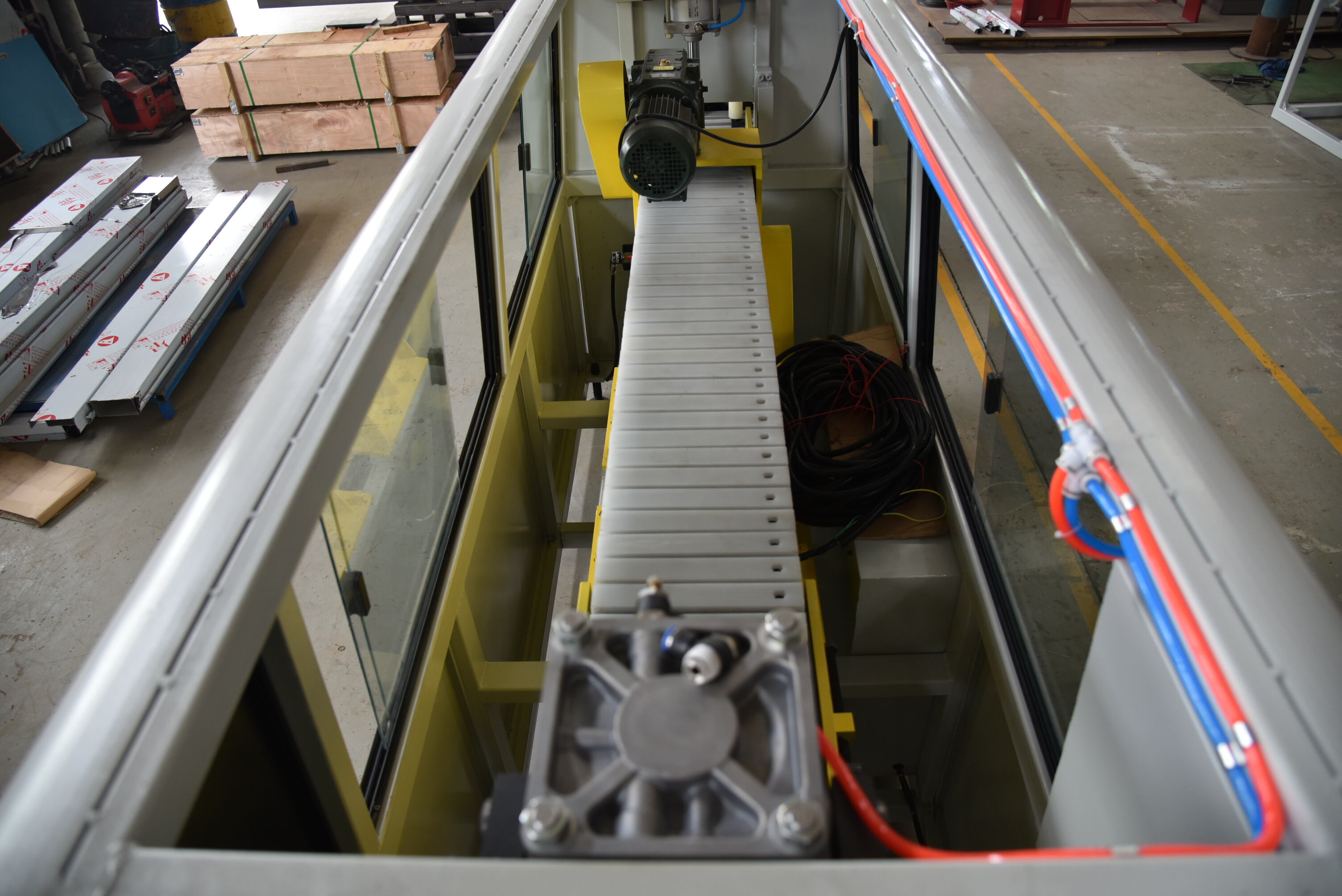

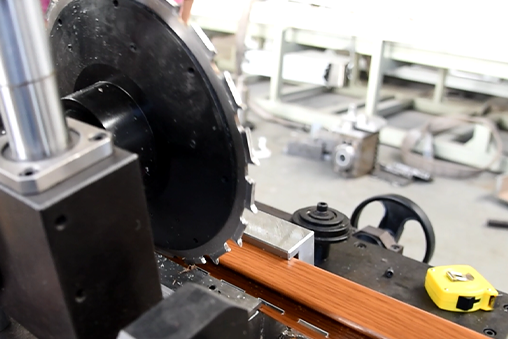

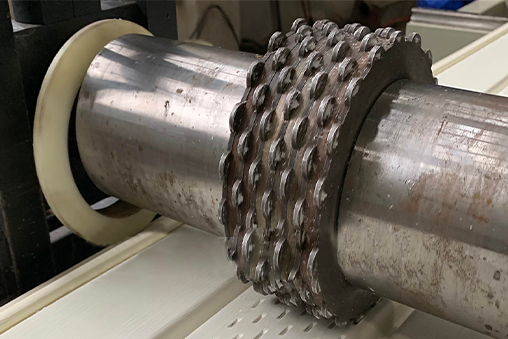

5.Perforating machine, haul-off machine, cutting machine and stacker

In a cutting-edge siding panel extrusion line, key components like the perforating machine, haul-off machine, cutting machine, and stacker play pivotal roles. The perforating machine meticulously punctures precise patterns into panels, facilitating controlled ventilation and enhancing design versatility. Following this, the haul-off machine ensures a seamless and uniform extrusion process, pulling the material through the line with precision. Subsequently, the cutting machine employs advanced technology to achieve accurate panel dimensions, optimizing efficiency and minimizing waste. Finally, the stacker organizes and assembles the finished panels, streamlining the production flow. Together, these components create a synchronized and efficient extrusion line, delivering siding panels with tailored perforations, precise dimensions, and organized stacking, meeting industry standards and customer expectations for quality and functionality in the construction materials sector.

Our friendly team would love to hear from you!