Pipe Extrusion Die Design: Creating the Perfect Pipes for Your Needs

In search of for an effective way to produce high-quality Pipes for the use or personal business? Consider Pipe Extrusion Die Design, along with Bonzer's product co rotating twin screw extruder. This innovation in the manufacturing industry can present a number of advantages and ensure safety in the production of your Pipes. We shall explore the different aspects, including it is application, how to use it, service, and overall quality.

One of several main benefits is the fact that it allows for the production of Pipes with consistent quality and dimensions, the same as extrusion equipment produced by Bonzer. This is because the Design of the Extrusion Die means that the molten used plastic in the method flows evenly and creates an uniform product. Additionally, Pipe Extrusion Die Design can produce Pipes with intricate shapes and patterns, rendering it a versatile activity a variety of applications.

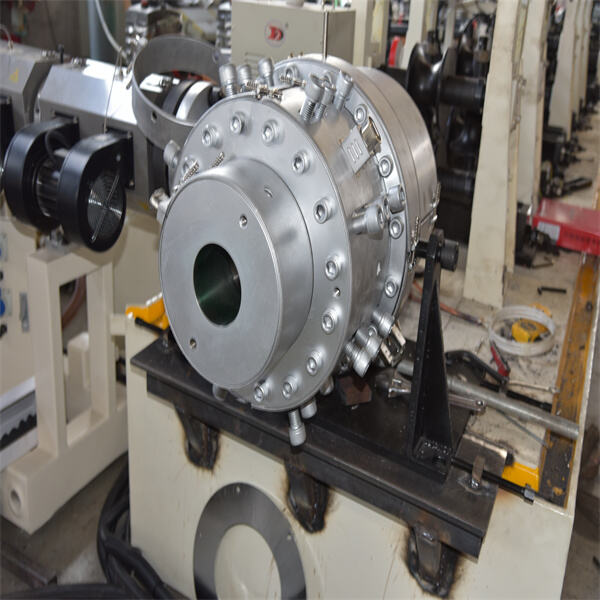

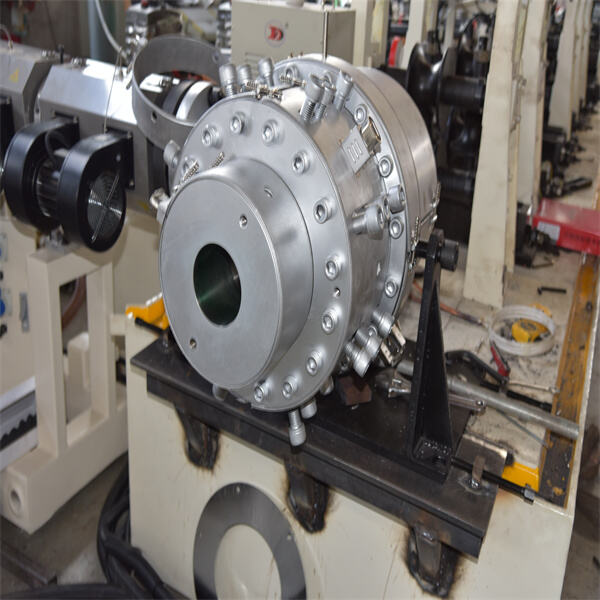

In recent years, Pipe Extrusion Die Design is now more innovative, with advancements in materials and technology, similar to the Bonzer's product like sheet extruder. For instance, new materials for Extrusion Dies have already been developed that will resist high temperatures and wear, making sure they stay longer and build greater quality Pipes. Additionally, computer-aided Design software has managed to make it much easier to create complex Extrusion Die shapes, leading to more intricate Pipe Designs.

Safety is a top problem any manufacturing process, and Pipe Extrusion Die Design is not any exception, identical to wpc extruder made by Bonzer. Among the safety features of Pipe Extrusion Die Design is the fact that it could be easily automated, decreasing the importance of workers to be close to the task. Additionally, Extrusion Dies can be Designed with features that prevent the workers from getting into contact with hot vinyl, reducing the chance of burns and other injuries.

Using Pipe Extrusion Die Design may be easy, especially with the help of trained professionals, as well as the Bonzer's plastic extruder. First, the vinyl was melted and then fed into the Extrusion Die. Next, the Extrusion Die shapes the plastic in to the desired dimension and shape. The Pipe is then cut and cooled into the suitable length. It’s important to notice that precise temperatures and pressures are fundamental in ensuring that the Extrusion Die produces the specified product.

Kunshan Bonzer Plastic Machinery Co., Ltd. is distinguishable to be a beacon of pipe extrusion die design in the field of synthetic gear. The business is specialized in quality and employs technology this can be quality this is certainly most certainly cutting-edge is strict procedures to make certain that their products or services or solutions or solutions or services or solutions meet industry requirements. These products will probably the shoppers are tested by our customers to be certain of its durability, accuracy, and reliability. Kunshan's dedication to quality goes without saying in just about every element that right was got by you. This may be the simple thing that makes Kunshan a brand name clients can trust which could make items that is usually top-notch.

Paying attention that most clients' requirements will be alter, Kunshan Bangze Plastic Machinery excels in providing solutions that can be modified. The organization collaborates closely featuring its customers to fully comprehend their demands, and then tailors the machinery properly. This action to tailoring helps you to make certain that consumers have gear that fits precisely due to their manufacturing objectives and operations, and a completely large amount of out of all the, combined with needs for the government. From design modifications to specific features, Kunshan Bonzer's dedication to customization empowers consumers to quickly attain effectiveness that is maximum setting them apart being an option that is top tailored machinery of plastic.

This is customer focus with this can potentially be pipe extrusion die design beyond the aim of purchase, Kunshan Bonzer takes pride in making use of its approach. The company is directed at fostering relationships that may be long-lasting having its consumers by assisting maintenance certainly comprehensive. A responsive consumer is an organization that is certainly efficient and sometimes willing to cope with inquiries, troubleshoot dilemmas, and in addition, make customers aware of yes help that is prompt. This solution is Kunshan Bonzer's to customer care and reinforces its reputation as be partner that is dependable within the synthetic materials gear sector.

Kunshan Bonzer Plastic Machinery is certainly a person who is well-established the industry of pipe extrusion die design. It is really knowledge this is certainly indispensable which includes allowed us to steadfastly keep up utilizing the evolving requirements about the market after a while, we now have developed understanding. We are able to provide clients and this can be direct solutions when it comes to their future jobs, based on the market and country you begin with once they spot an purchase while watching product which is final 2 months. The expertise this will be really vast of business will offer you customers brand solutions that are brand new guaranteed to endure the test of that right time period.