The construction and manufacturing space is one in which ideas to advance industries are what moves them forward. An intriguing market where such innovations are on greater viewing is that of a UPVC profile manufacturer. Heavy on profiles with the latest in tech, and a focus on being kind to Mother Earth. Bonzer has become known for its exceptional work in this field, with a production line that adheres fully to all industry specifications and often surpassing them.

Updates In UPVC Profile Production

With more and more technological changes, UPVC Profile Manufacturing Landscape has revolutionized at a high end. Automation in Extrusion Systems has redefined the way of production making it more accurate, less tolerant and increasing repeatability in final product which intern optimizes raw material consumption. In addition, the feat of integrating Integrated Recycling Technologies into OEMs facilitates scavenging and reusing recyclable material leading to new components in an attempt towards more sustainable production process. With the real-time data collection via IoT sensors, production has been further improved by continuously tracking some of its critical parameters (mean time before failure), optimisation of processes and enabling predictive maintenance.

Expand Your Business with our UPVC Profiles

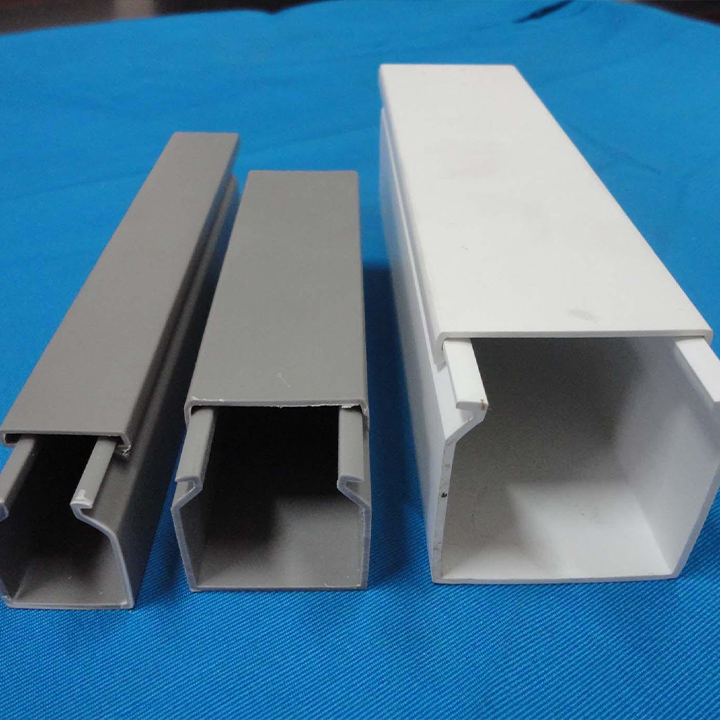

Our UPVC Profile extrusion machines come with cutting edge production lines to take the growth of your business more than a notch higher. We can help you reduce production costs and machine downtime by incorporating state-of-the-art machinery into your operations. These Upvc bathroom ceiling panels are perfect for manufacturing windows, as well as proper fencing solutions including elsewhere in the industrial market segment.

Making Upvc Profile Producing Sustainable

Sustainability is no longer optional in the manufacturing of today's marketplace. The case study of Upvc bathroom ceiling profile production lines illustrates a commitment to sustainable practices, where use of recycled materials, energy efficiency and increasing building lifespan have been highlighted as some the measures that can be implemented in our facilities with far-reaching potential for waste reduction along with carbon emissions. Our eco-friendly manufacturing lines not only help the environment by following global green initiatives, they also generate huge savings.

UPVC Profiles For Different Sectors

Realizing the unique requirements of different sectors, we specializes in providing system designed for PVC/UPVC window door frames profile extrusion line profile manufacturing. Our team works closely with you to customize profiles and components that can meet even the most individual needs. By following this personalized approach and given subtle industry interests, we also help our clients stand out in the market & take advantage of competition for their advantages.

Its Effects on the UPVC Profile Making Process

Our process was built on one principle all along - of being efficient at our work without compromising with the quality. Thanks to the use of more advanced extruders, automation solutions and process optimization software we make sure our extrusion lines perform excellent results with high productivity, less labor costs while decreasing errors. This smart evolution - between cutting-edge technology and a keen eye on the detail ensure we can perform efficiently, consistently quality outputs while continuing with sustainable manufacturing.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

KA

KA