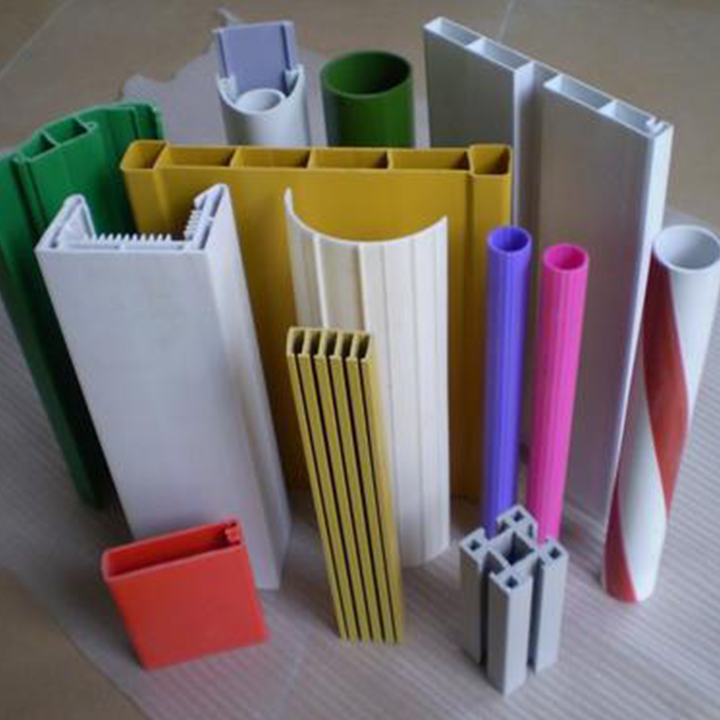

Material technology has played a very large part in design opportunities and sustainability best practices when it comes to construction and architecture. One such earth-positive innovation falling under the broad pool of advancements-Profiles for doors and windows in UPVC (Unplasticized Polyvinyl Chloride) by Bonzer. The machinery process of creating this sort data plays a pivotal role, making not only buildings but the future construction world. Discussing the technologies, advantages and effects of UPVC door and window profile making machines: The latest leap of science and technology contributes to more architectural significance (indeed); environmental friendliness ever than before; high-tech potential exploited in them; a greater need for quality equipment with customers.

UPVC Door and Window Profile Machinery Advances

The advancement of these UPVC profile making machines has been game changing. But a host of variables mean the machines in use today range from manual extrusion processes to fully automated, computer-controlled systems that provide real-time monitoring. With more advanced software profiles for intricate designs, this ensures that the walls and overall engineering design are perfectly accurate on both dimensions anoint quality of surface finish as per international architectural standards. In addition, it integrates IoT (Internet of Things) technology that supports remote diagnostics and predictive maintenance which improves operational efficiency while reducing downtime.

On the other hand, advancement in UPVC profile making machines has come into light for changed ways of manufacturing doors and windows. As we moved from labor to technology, the Upvc window profile extrusion machine increased in capacity as cheaper and quickly with a lifestyle even that could be automated because of high consumption. Because of this shifting from manual to automation has not only scaled the efficiency but multiplied it with effectiveness, making UPVC profiles play a significant role in assisting construction industry strive and meet its rising demands.

Read on to explore the key ways in which UPVC door and window machines help shape contemporary architecture.

Versatile and sturdy UPVC profiles have come to the fore in modern architectural styles - combined with all that’s been said above of course. Helping create beautifully crafted, energy-efficient windows and doors without compromising on performance. They enable making of complicated geometric shapes and large-scale glazing leading to daylighting strategies hence reducing use of artificial lighting. And loggers do this all to make plants for creating sustainable, low-carbon footprint buildings that support the global policies on green architecture.

The UPVC door and window machines also have a wide impact on aesthetics as well. The vending machines are changing the architectural environment and providing energy-efficient and ecologically sustainable solutions. By using PVC/UPVC window door frames profile extrusion line in building designs, architects and builders can not only make buildings more aesthetic but also help the world to go greener.

Environment-friendly UPVC Profiles Manufacturing

The manufacture of UPVC profiles lies at the very heart of sustainability. Although largely industrialized, the process stresses resource efficiency and waste minimization. High-tech equipment helps material efficiency where excess materials are cut with extreme accuracy to avoid scrap and re-ploughed back into the system. In addition, UPVC is recyclable by nature so the production cycle closes allowing waste to be recycled into new profiles. This would cut the environmental footprint of this manufacturing sector by a large margin and keep in line with circular economy principles.

UPVC is also environmentally beneficial and the manufacturers of UPVC profiles focus on producing almost unbreakable products. The use of sophisticated machinery and advanced production processes allows the profile to maintain its quality over many years, thus enhancing building performance as well as reducing replacements required on a frequent basis.

Enable the Advanced UPVC Profile Making Machines to Show Its Potential

Industrial 4.0 has made the uPVC door and window profile making machines smarter, intelligent and adaptable as well. These systems even can self-optimize production with AI driven algorithms by using real time data to predict and adapt low volume couple differences of raw materials as well as external conditions. This high degree of automation improves the consistency, as well as speeds up production rates to allow manufacturers to reach increasing numbers of custom tooling solutions and still meet quality requirements.

Furthermore, the incorporation of smart features into UPVC profile manufacturing machine has brought significant change in the production system and made it smoother and more accurate. By using the most modern technology available, manufacturers can create UPVC profiles that are capable of delivering unbeatable quality and cutting-edge performance levels never previously seen in this industry - essentially rewriting what is thought to be possible today.

The Burning Need for Best Door and Window Profile Machines

Rising prevalence of such sustainable constructional solutions around the world is likely to impact positively on their global usage thereby demand high-quality UPVC profile making machines and in increased numbers. UPVC products offer long-lasting benefits such as the ability to provide insulation, endure adverse weather conditions and generally require little up-keep recognized by architects, builders and homeowners. As a result, manufacturers using cutting edge machinery for profiles that meet these high standards will be in the best possible place to take control of some significant market share. The journey towards research and innovation in this field highlights the need for continuous R and D, evolution with changing technology trends.

In addition, the rising need for high-end door and window profile systems is indicative of a greater realization about eco-friendly construction. While environmental responsibility and energy efficiency become an increasingly important focus for more stakeholders in the construction industry, so too does demand grow for advanced UPVC machinery that can meet these requirements. Businesses who make these investments in modern technology and equipment to fulfill their needs are not just staying up-to-date but they're also delivering positive change across the industry for a more environmentally sustainable future.

To conclude, the world of UPVC door and window profile making machines is an ever-changing horizon wherein technological advancements truly meet environmental sustainability. These Custom profile extrusion machines are reshaping the built environment as they continue to evolve and, in so doing, redefining construction's role on sustainability. This, with every frontier broken on this path towards a future where architectural vision marries ecological sensibility builds our world better for generations yet to come.

Table of Contents

- UPVC Door and Window Profile Machinery Advances

- Read on to explore the key ways in which UPVC door and window machines help shape contemporary architecture.

- Environment-friendly UPVC Profiles Manufacturing

- Enable the Advanced UPVC Profile Making Machines to Show Its Potential

- The Burning Need for Best Door and Window Profile Machines

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

KA

KA