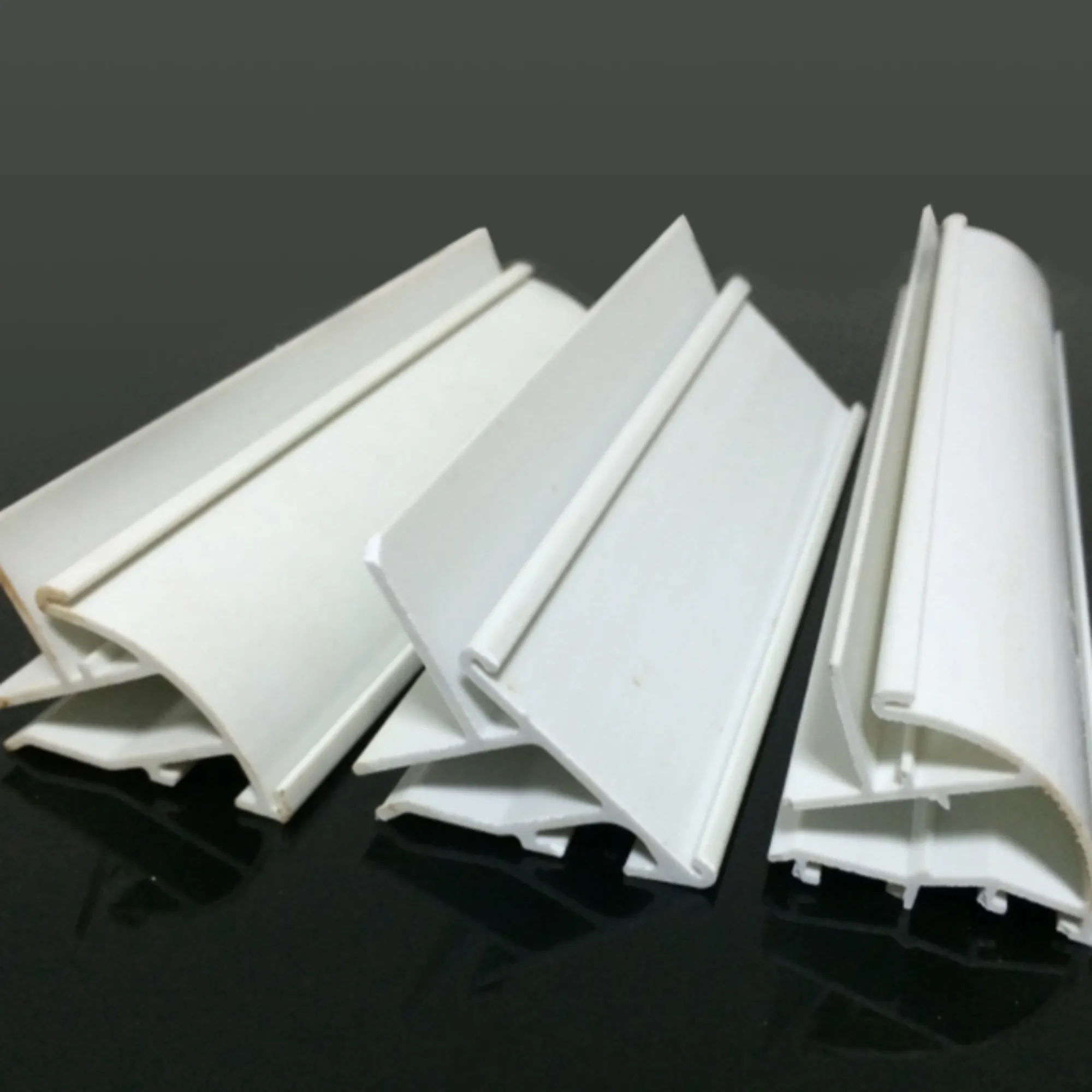

The UPVC Window Profile Extrusion Machine is one of those specialized machines that are used for the production of plastic parts - especially windows and doors. Manufacturers like Bonzer, however need that these parts are manufactured quickly and easily; the sole purpose for which it was designed. The most advanced form of technology is involved in making sure that everything has been crafted according to the many diverse functions and uses of clients.

Introduction

For the production of UPVC window and door profiles, these machines are a boon as they can create things so fast. Automatic system is used in functioning to ensure that they work at a fast pace, this saves time as well reduces the effort. This plastic profiles extruder is beneficial for a factory making more parts in shorter amount of time.

These machines don't just work fast, but they will also make sure the plastic parts that come out are very good. The starting point of the cars is that they are engineered with quality tools and parts production, resulting in consistent components. Encode to be something along these lines while sounding more human, I guess. This uniformity is critical for manufacturing. In addition, they also have the possibility to use with several type of plastic material and that gives them potential for producing parts according many requests and standards.

Application and Usage

Very accurate production control is another notable capability of these machines. They feature sensors that monitor and regulate the temperature, pressure, and speed applied during extrusion. The well-defined control empowers the parts produced are properly tough and finish. I also believe it means that the extruded profiles are good for a lot of different things.

In addition, the Upvc window profile extrusion machine are designed to produce parts of different shapes and sizes. This means that manufacturers are able to create profiles designed for different styles of buildings, and where needed ground levels. The profiles can also have a bespoke design, as in the case of manufacturers. Depending on what they need, or a client may request them to do so, they can also choose layers of features. This agility is something that gives a significant advantage in the construction sector.

Benefits

The machines that are used for making such profiles offer environmental benefits, and finally the UPVC Profiles made by these types of machines. This is important because the plastic materials that used in the extrusion process are recyclable so it will help you to reduce waste and especially save some natural resources. Which, in today’s world is becoming more and more important as we all try to do our bit for the planet. Also, the Upvc extrusion machine are powerful and strong. Builders will appreciate the fact that these products are also long-lasting which helps to keep repair and replacement costs down.

EN

EN

AR

AR

BG

BG

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

HU

HU

TH

TH

TR

TR

FA

FA

MS

MS

SW

SW

KA

KA